-

Address

Wangjiang, Xingtian No 2 Rd, Xingning, Meizhou City, Guangdong Province, China.

- Email:enquiries@apalloy.com

- Phone:+86 0753 3354369

- WhatsApp: +86 18813765785

The precision of pump casting parts has a critical impact on the integral pump, mainly reflected in the following aspects:

1、 Performance aspects

A. Efficiency

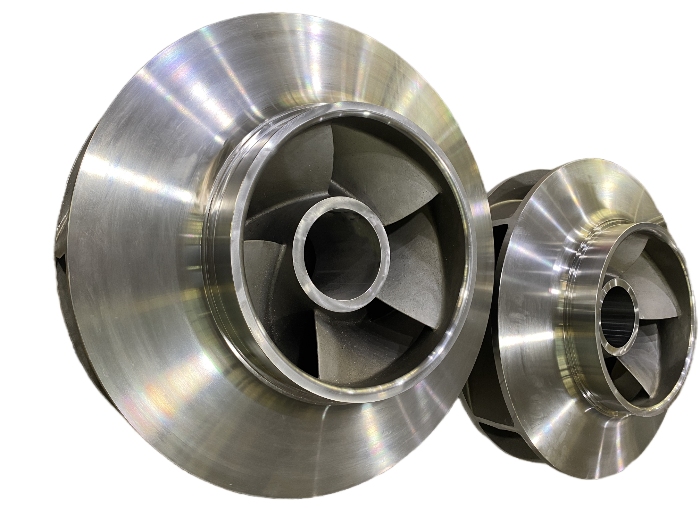

High-precision cast fittings ensure a more regular and smooth flow path shape inside the pump. This reduces the resistance of fluid flowing in the pump and improves the hydraulic efficiency of the pump. You can imagine a fluid running on a flat, wide highway, flowing smoothly through the pump and reducing energy losses.

High fitting accuracy between fittings reduces the possibility of leakage. For example, if the clearance between impeller and pump casing is well controlled, the leakage of fluid from high pressure zone to low pressure zone can be greatly reduced, thus improving the volumetric efficiency of pump.

B. Stability

High-precision casting accessories provide greater stability during operation. The dimensional fit between the components is accurate, so that the pump will not have vibration and noise caused by looseness or unbalance when running at high speed. This not only increases the pump life, but also provides a more stable and reliable operating environment for the entire system.

For applications where stability is critical, such as chemical processes, nuclear power plants, etc., high-precision casting accessories are essential. Any minor instability factor may lead to serious consequences.

2、 Reliability aspects

A. Service life

High-quality cast fittings with high precision and uniform material for greater pressure and wear. During long-term operation, it is not easy to have cracks, deformation and other problems, thus prolonging the overall service life of the pump.

For example, the impeller has high casting precision, good dynamic balance performance, more uniform centrifugal force generated when rotating at high speed, reduced the wear of bearings and other parts, and improved the reliability of the pump.

B. Maintenance Cost

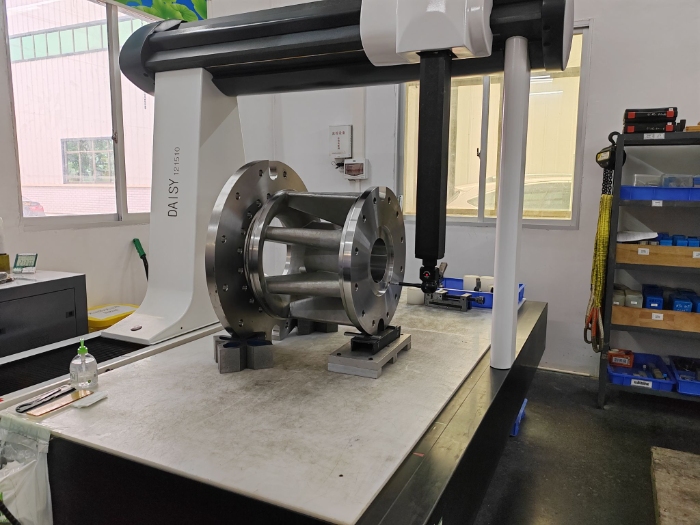

Precision cast fittings make installation and replacement easier and quicker. Due to accurate size and tight fit, the debugging time and difficulty in the installation process are reduced. At the same time, it is easier to find suitable replacement parts during maintenance, and the maintenance cost is reduced.

If the precision of casting parts is low, frequent failures and maintenance may be caused, which not only increases the maintenance cost, but also affects the production schedule.

3、 Aspects of adaptability

A. Adaptability under different working conditions

High-precision casting accessories can be customized and manufactured according to different working conditions. For example, for special working conditions such as high temperature, high pressure and corrosive medium, proper materials and processing process can be selected to ensure normal operation of the pump under severe environment.

The high precision of accessories can also make the pump easier to realize the modular design, facilitate the combination and adjustment according to different needs, and improve the adaptability and flexibility of the pump.

B. Compatibility with other equipment

Pumps typically need to work in conjunction with other equipment such as motors, piping, valves, etc. High-precision casting accessories can be connected and matched with these equipment to ensure the operation efficiency and stability of the whole system.

If the pump casting fittings are of low accuracy, there may be mismatches with other equipment, affecting the performance and reliability of the entire system.

Wangjiang, Xingtian No 2 Rd, Xingning, Meizhou City, Guangdong Province, China.