-

Address

Wangjiang, Xingtian No 2 Rd, Xingning, Meizhou City, Guangdong Province, China.

- Email:enquiries@apalloy.com

- Phone:+86 0753 3354369

- WhatsApp: +86 18813765785

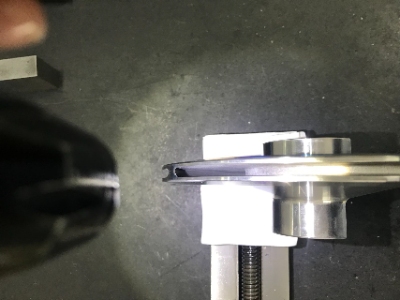

Sewage pump is a kind of pump product integrating pump and motor and working under liquid at the same time. Compared with general horizontal pump or submersible sewage pump, the sewage pump has compact structure and small floor area. Aopu can customize different types of impellers according to drawings for the small sewage pump that is easy to install and maintain and can be installed freely. Large sewage pumps are generally equipped with automatic coupling device for automatic installation and maintenance. Long continuous operation time. As the pump and the motor are coaxial, the shaft is short and the rotating parts are light, the load (radial) on the bearing of the sewage pump is relatively small and the service life is much longer than that of the general pump. There is no cavitation damage and water diversion. Especially, the latter one brings great convenience to the operator. Low vibration noise, low motor temperature rise, no environmental pollution.

The impeller types of sewage pump are respectively introduced as follows:

The impeller structure is divided into four types: blade type (open type and closed type), swirl type, flow passage type (including single flow passage and double flow passage) and spiral centrifugal type. The open semi-open impeller is easy to manufacture. When the impeller is blocked, it can be easily cleaned and maintained. However, in long-term operation, the clearance between the blade and the side wall of the water pressure chamber will be enlarged under the abrasion of particles, thus reducing the efficiency. Moreover, the increase of clearance will destroy the differential pressure distribution on the blade. It not only generates a large amount of vortex loss, but also increases the axial force of the pump. At the same time, the stability of the fluid flow in the flow channel is damaged due to the increased clearance, making the pump vibrate. This type of impeller is not easy to transport the medium containing large particles and long fibers. From the performance point of view, this type of impeller has low efficiency, the highest efficiency is about 92% of the common closed impeller, and the head curve is relatively flat.

Pumps using this type of impeller because the impeller partially or completely retracts from the plenum flow path. So the non-blocking property is good, and the passing capacity of particles and long fibers is strong. Particles flow in the water pressure chamber under the promotion of vortex generated by impeller rotation. The movement of suspended particles does not generate energy, and energy is exchanged with the liquid in the flow passage. In the flow process, the suspended particles or long fibers are not in contact with the worn blades, the blades are slightly worn, and the clearance is not enlarged due to abrasion, so the efficiency will not be seriously reduced in long-term operation. The pump with impeller of this type is suitable for pumping media containing large particles and long fibers. In terms of performance, the impeller efficiency is low, only about 70% of the common closed impeller, and the head curve is relatively flat.

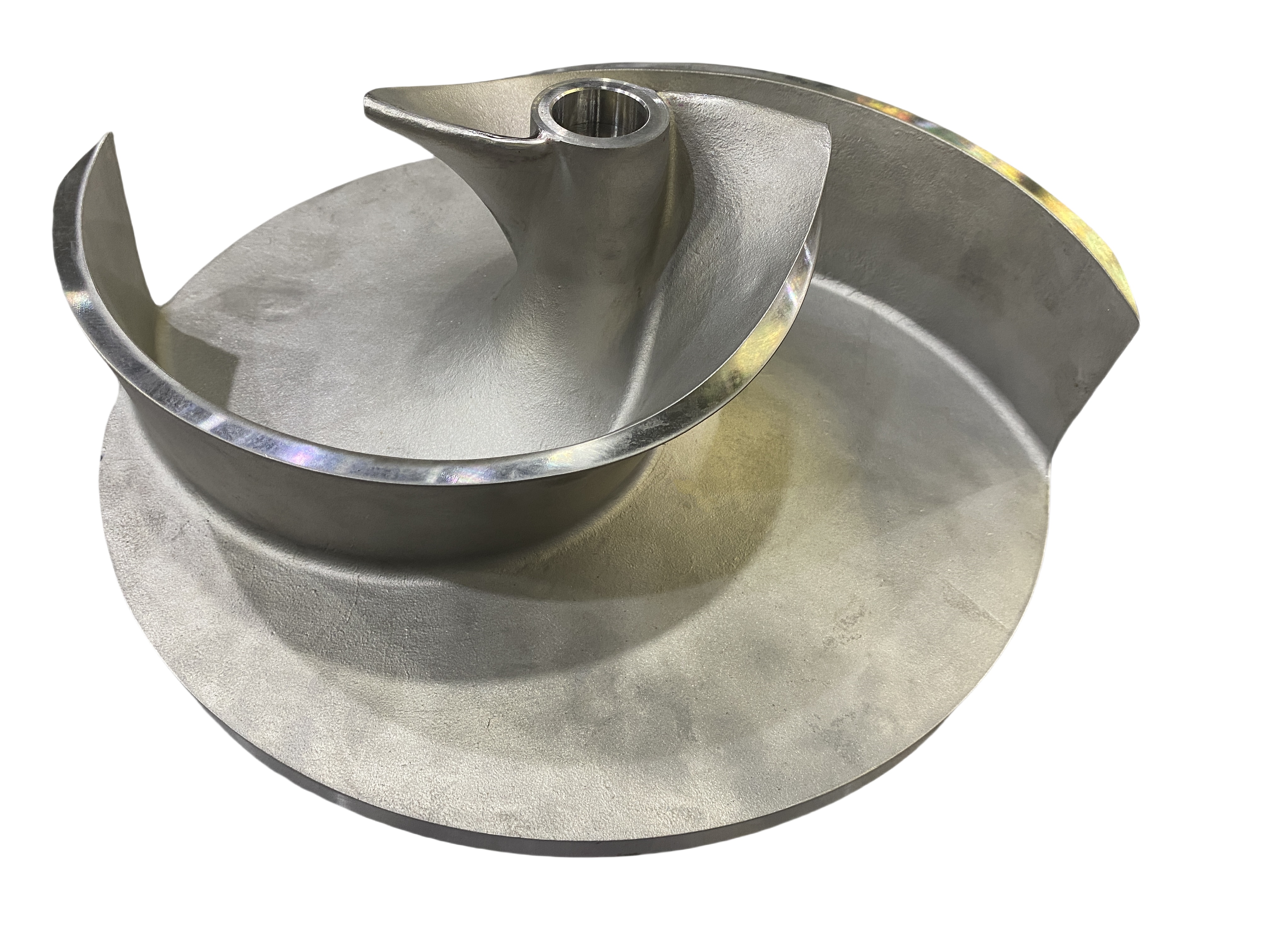

2. Screw centrifugal impeller

The blades are twisted helical blades that extend axially from the suction on a tapered hub. The pump with this impeller has the functions of positive displacement pump and centrifugal pump. When the suspended particles flow through the blade, they will not impact any part of the pump, so the pump has good nondestructive property. Less destructive to conveyed materials. Due to the propelling effect of screw and strong trafficability of suspended particles, the pump with impeller of this type is suitable for pumping medium containing large particles and long fibers as well as medium with high concentration. It has obvious characteristics when there are strict requirements for the damage of transmission medium.

3. Runner type impeller

This impeller is a vaneless impeller and the impeller passage is a curved passage from the inlet to the outlet. Therefore, it is suitable for pumping media containing large particles and long fibers. Good anti-blocking performance. In terms of performance, the impeller efficiency of this type is almost the same as that of common closed impeller, but the head curve of impeller pump of this type is relatively steep. The power curve is relatively stable and it is not easy to produce the problem of overpower. However, the cavitation performance of this type of impeller is not as good as that of common closed impeller, especially suitable for the pump with pressure inlet.

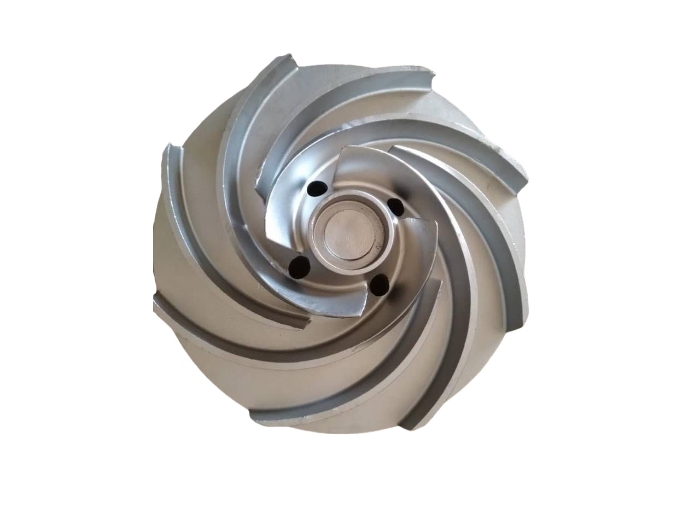

4. Closed type impeller

This type of impeller has a normally high efficiency. In case of long-term stable operation, the axial force of the pump with impeller of this type is small, and auxiliary vanes can be set on the front and rear cover plates. The auxiliary blade on the front cover plate can reduce the vortex loss at the impeller inlet and the wear of particles on the sealing ring. The secondary blades on the rear cover plate not only balance the axial force, but also prevent the suspended particles from entering the mechanical seal cavity to protect the mechanical seal. However, this impeller has poor non-blocking property and is easy to be wound, so it is not suitable for pumping the untreated sewage medium containing a large number of particles (long fibers).

To sum up, regardless of any series of sewage pump impeller, it is only a combination of different types of impeller and different types of pressure chamber according to the transmission medium and installation requirements, as long as the impeller and pressure chamber can be optimized. Various performances of the pump will be guaranteed.

Wangjiang, Xingtian No 2 Rd, Xingning, Meizhou City, Guangdong Province, China.